|

|

|

KinetiChem, Inc. provides novel chemical reactor systems to entities seeking rapid scalability, efficient manufacturing processes and a unique competitive advantage in the marketplace.

KinetiChem, Inc. provides novel continuous flow chemical reactor systems to those seeking rapid scalability, efficient manufacturing processes and a unique competitive advantage in the marketplace.

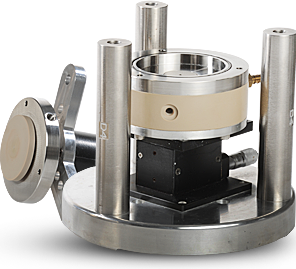

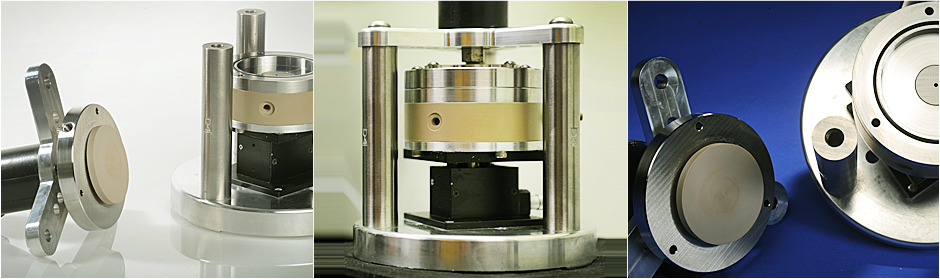

KinetiChem's SynthetronTM reactor technology enables accelerated production rates for chemical reaction processes used in the manufacture of fine chemicals, agrochemicals and active pharmaceutical ingredients.

Recent developments in flow chemistry approaches have led to a realization that this methodology can be used to efficiently, safely and effectively produce milligram to multi-ton scale processes that are economically viable and preferential over similar batch based processes. Flow chemistry has been shown to exhibit more favorable reaction profiles due to careful control of critical reaction parameters such as reagent concentration and reaction temperature. Additionally, flow chemistry approaches have been demonstrated to enable the realization of more efficient chemical transformations through the use of more concentrated reaction streams, along with lower catalyst loadings, to produce higher yielding reaction outcomes.

While the fundamental aspect of performing chemistry continuously in flow is well understood, not all commercial systems operating in this fashion are identical. There are many different reactor system platforms and overall approaches available to enable a scientist to develop a flow chemistry process. Consideration of ease of use, cost effectiveness of the system, overall scalability across a broad range, and ability to conduct a wide range of processes with broad material compatibilities are all important aspects to be considered when choosing a particular flow chemistry platform.

KinetiChem's Synthetron™ systems provide rapid discovery and scale-up of innovative products and processes with a concurrent dramatic reduction in time-to-market over existing methodologies. KinetiChem's reactor systems, capable of multiple kilo-gram per hour processes while only occupying less than half a typical fume hood, operate in continuous flow and enable reaction methodologies that are scalable on demand to quickly deliver larger quantities of products without the need for lengthy scale-up development times. KinetiChem is working on developing a robust line of Synthetron reactor systems capable of delivering a diverse array of chemical manufacturing methods at a broad range of scales. Contact us to find out more about the Synthetron technology and how it can help you further your processes of interest today!

- Home

- |

- TECHNOLOGY

- |

- About US

- |

- Contact US

©Copyright © 2011, KinetiChem, Inc. All Rights Reserved

Los Angeles Web Design by Altadar